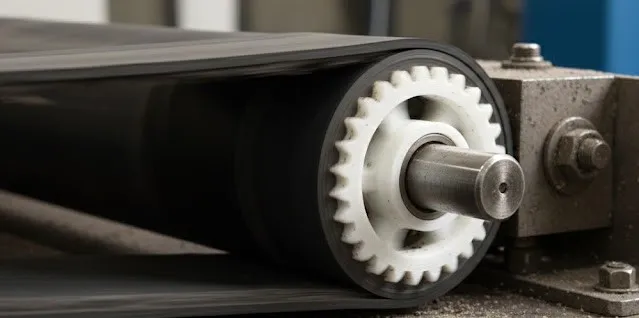

PA6 (Nylon 6)

High Impact & Fatigue Resistance

Standard Nylon

PA6 is a tough, wear-resistant engineering polymer. It combines excellent mechanical strength with very high impact resistance. It resists oils and greases, making it reliable for moving parts like gears and bushings.

Best For: Gears, Pulleys, Clamps, Moving Assemblies.

Best For: Gears, Pulleys, Clamps, Moving Assemblies.

| Tensile Strength | 70 MPa ★★★★★ (Strong) |

| Tensile Stiffness | ~2.6 GPa ★★★☆☆ (Rigid) |

| Impact Resistance | High ★★★★★ (Tough) |

| Fatigue Resist. | Excellent ★★★★★ (Durable) |

| Chemical Resist. | High ★★★★☆ (Oils/Fuels) |

| Heat Resistance | ~100 °C ★★★★★ (High) |

PA12 (PAHT)

Low Moisture & Dimensional Stability

Stable

PA12 absorbs far less water than PA6, resulting in more predictable tolerances and stable mechanical properties in humid environments. It offers excellent chemical and fuel resistance.

Best For: Automotive, Industrial Housings, Fuel Lines.

Best For: Automotive, Industrial Housings, Fuel Lines.

| Tensile Strength | 50 MPa ★★★★☆ (Reliable) |

| Tensile Stiffness | ~1.8 GPa ★★★☆☆ (Semi-Flex) |

| Moisture Absorp. | Very Low ★★★★★ (Stable) |

| Chemical Resist. | Excellent ★★★★★ (Fuels) |

| Heat Resistance | ~90 °C ★★★★☆ (High) |

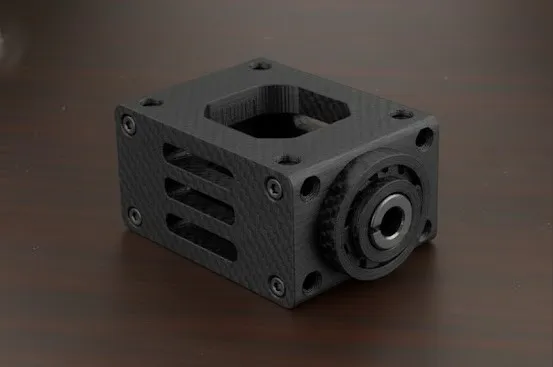

PA6-CF

Carbon Fiber Reinforced Nylon 6

High Stiffness

Combines the wear resistance of Nylon with the extreme stiffness of Carbon Fiber. Ideal for structural components requiring high load capacity, minimal deformation, and fatigue stability.

Best For: Drone Parts, Robot Arms, Manufacturing Jigs.

Best For: Drone Parts, Robot Arms, Manufacturing Jigs.

| Tensile Strength | 90+ MPa ★★★★★ (Very Strong) |

| Tensile Stiffness | ~6.0 GPa ★★★★★ (Rigid) |

| Impact Resistance | High ★★★★☆ (Tough) |

| Fatigue Resist. | Excellent ★★★★★ (Structural) |

| Heat Resistance | ~150 °C ★★★★★ (Extreme) |

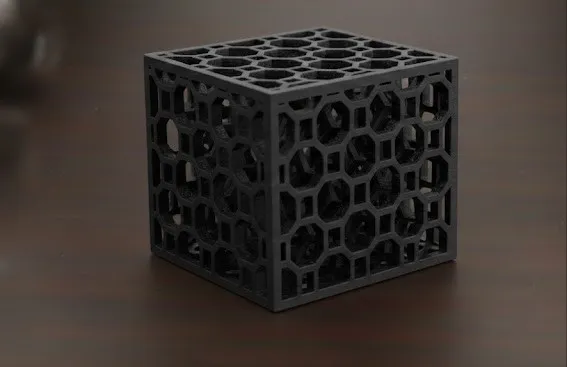

PA6-GF

Glass Fiber Reinforced Nylon 6

Cost Effective Stiffness

Glass fiber reinforcement delivers exceptional stiffness and thermal performance at a lower cost than Carbon Fiber. It offers very low deformation under load.

Best For: Rigid Housings, Enclosures, Fixtures.

Best For: Rigid Housings, Enclosures, Fixtures.

| Tensile Strength | 80 MPa ★★★★★ (Strong) |

| Tensile Stiffness | ~7.0 GPa ★★★★★ (Rigid) |

| Impact Resistance | Moderate ★★★☆☆ (Solid) |

| Creep Resist. | High ★★★★★ (Stable) |

| Heat Resistance | ~120 °C ★★★★★ (Very High) |

PA12-CF

Carbon Fiber PA12 (Low Moisture)

Precision + Stiffness

Combines the low moisture absorption of PA12 with the strength of Carbon Fiber. This is the ultimate material for precision structural parts that must hold tight tolerances in humid environments.

Best For: Precision Jigs, Aerospace Parts, Humid Environments.

Best For: Precision Jigs, Aerospace Parts, Humid Environments.

| Tensile Strength | 90+ MPa ★★★★★ (Strong) |

| Tensile Stiffness | ~8.0 GPa ★★★★★ (Rigid) |

| Moisture Absorp. | Very Low ★★★★★ (Stable) |

| Accuracy | Excellent ★★★★★ (Precision) |

| Heat Resistance | ~130 °C ★★★★★ (Extreme) |

PA12-GF

Glass Fiber PA12

Durable

High rigidity, excellent dimensional stability, and very low moisture absorption. Glass reinforcement makes this ideal for parts maintaining shape in hot/humid conditions.

Best For: Outdoor Housings, Mounts, Covers.

Best For: Outdoor Housings, Mounts, Covers.

| Tensile Strength | 75 MPa ★★★★★ (Strong) |

| Tensile Stiffness | ~6.0 GPa ★★★★★ (Rigid) |

| Moisture Absorp. | Low ★★★★★ (Stable) |

| Chemical Resist. | High ★★★★☆ (Good) |

| Heat Resistance | ~110 °C ★★★★★ (Very High) |

PPA-CF (High Performance)

Semi-Aromatic Carbon Nylon

Aerospace Grade

PPA-CF is a semi-aromatic nylon designed for the most demanding applications. It offers outstanding thermal stability (up to 150°C), extremely high stiffness, and excellent chemical resistance. It replaces metal in many engine-bay applications.

Best For: Engine Parts, Aerospace Brackets, Metal Replacement.

Best For: Engine Parts, Aerospace Brackets, Metal Replacement.

| Tensile Strength | 140+ MPa ★★★★★ (Metal Like) |

| Tensile Stiffness | ~12.0 GPa ★★★★★ (Max) |

| Thermal Stability | Excellent ★★★★★ (No Creep) |

| Chemical Resist. | Extreme ★★★★★ (All) |

| Heat Resistance | ~150 °C+ ★★★★★ (Extreme) |

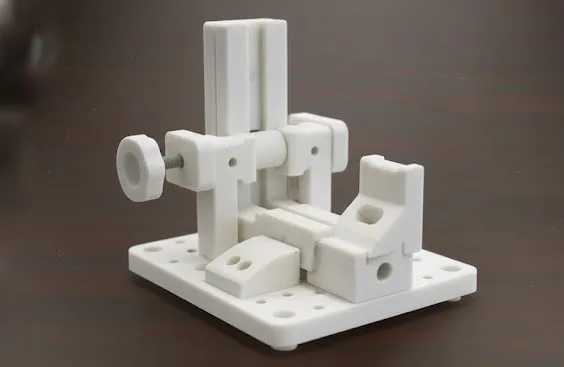

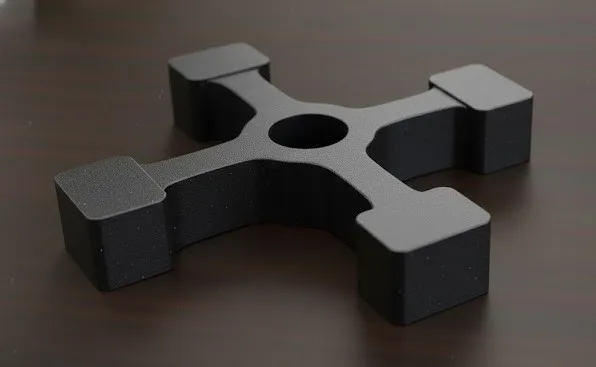

Custom Prototyping

Your Design, Our Engineering

Print on Demand

Need custom Nylon parts?

Nylon printing requires specialized high-temp printers and dry-boxes. We have the industrial equipment to handle PA6, PA12, and PPA composites reliably.

Services: CAD Design, Reverse Engineering, Batch Production.

Nylon printing requires specialized high-temp printers and dry-boxes. We have the industrial equipment to handle PA6, PA12, and PPA composites reliably.

Services: CAD Design, Reverse Engineering, Batch Production.

| Max Build Vol | 256 x 256 x 256 mm (Large Scale) |

| Accuracy | ± 0.1 mm (Precision) |

| Lead Time | 4–10 Days (Turnaround) |

| File Types | STL, OBJ, STEP (CAD Ready) |

| Min Order | 1 Unit (No Minimum) |

| Design Service | Available (Hourly Rate) |

Frequently Asked Questions about Nylon

What is the difference between PA6 and PA12?

**PA6** is tougher and more impact resistant but absorbs moisture easily. **PA12** absorbs very little moisture, making it better for precision parts and humid environments, though it is slightly less impact resistant.

Why use Carbon Fiber (CF) Nylon?

Standard Nylon is somewhat flexible. Adding Carbon Fiber makes it extremely stiff (rigid) and increases its heat resistance. It is perfect for replacing metal brackets and fixtures.

Are these materials waterproof?

Standard PA6 is hygroscopic (absorbs water) and will swell slightly over time. **PA12** and **PPA** are much more resistant to water and chemicals, making them suitable for functional fluids and outdoor use.